| Applications of Polyethylene Glycol Hydrogels in Wound Healing and Regenerative Medicine | |||||||||||||||||||||||||||||||

| An Excerpt from: Hutanu D, Frishberg MD, Guo L, Darie CC (2014) Recent Applications of Polyethylene Glycols (PEGs) and PEG Derivatives. Mod Chem appl 2:132. doi: 10.4172/2329-6798.1000132 | |||||||||||||||||||||||||||||||

| A major reported use of polyethylene glycols in 2014 scientific papers is for the development of hydrogels [14,19,38–56]. Among the common uses of PEG hydrogels are the use as adhesives for wound closure, as controlled release matrices for therapeutics, for wound healing, as part of medical devices, and as regenerative medicine tools.A biodegradable cytocompatible bioadhesive hydrogel system was developed by Jeon et al. [47] from on oxidized methacrylated alginate/8-arm polyethylene glycol amine used for culture of human bone marrow-derived mesenchymal stem cells. The swelling behavior, degradation profiles, and storage moduli of the hydrogel bioadhesive were adjusted by varying the degree of oxidation of the alginate. The adhesion level was enhanced on a porcine skin model as compared to commercially available fibrin glue.Another bio-adhesive hydrogel, Catechol-containing 4-armed PEG end-capped with dopamine, was researched by Cencer et al. [55]. Studies on the effect of pH on the rate of intermolecular cross-linking and adhesion to biological substrates allowed the identification of the optimal buffering pH for formulation of the adhesive. When tested as an adhesive for pericardium tissues, a formulation pH of 7.4 provided the ideal balance of curing rate, mechanical properties, and interfacial binding ability for the Catecholcontaining 4-armed PEG hydrogel end-capped with dopamine.Progress on research and development of regenerative therapies aided by PEG hydrogel matrices is reported in several 2014 publications. As an example, a study by Frith et al. [39] describes a combination of mesenchymal progenitor cells with a potentially injectable PEG/ hyaluronic acid degradable hydrogel with a covalently bound pentosan polysulphate, that showed promise as therapy for the regeneration of the cartilage tissue. The molecular weight of the polyethylene glycol chain does not have a significant effect on cell division and sulfated glycosaminoglycan production as part of composite hydrogels [46].Likewise, for regenerative medicine purposes, Hoffman et al. [48] created a “tissue engineered periosteum”, utilizing hydrolytically degradable PEG hydrogels to transplant and localize mesenchymal stem cells to allograft surfaces. The approach increased the autograph healing-graft vascularization, the endochondral bone formation, and the biomechanical strength, when compared to untreated allografts. As a drawback, the process of endochondral ossification was delayed compared to untreated allografts, requiring future supplementation of the hydrogels with additives to expedite the ossification process for treatment of critical sized bone defects.

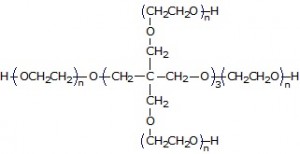

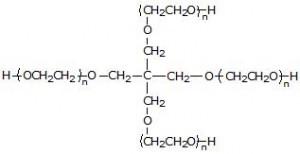

Nguyen et al. [44] controlled the in situ osteogenic differentiation of encapsulated stem cells in polyethylene glycol hydrogels by employing localized, and prolonged delivery of siRNA and/or miRNA interfering molecules. Moreover, differentiation of encapsulated human mesenchymal stem cells down the osteogenic lineage was achieved by Hao et al. [14] by in-situ cell culture in a 4 arm PEG hydrogel scaffold, by varying the rate and type of the hydrogel degradation. A 4arm PEG hydrogel was synthesized via a mixed-mode step-and-chain-growth photo-polymerization in visible light, using functionalized 4-arm polyethylene glycol as a backbone macromer, eosin-Y as a photosensitizer, a di-thiol containing molecule as co-initiator/cross-linker, and N-vinylpyrrolidone (NVP) as a gelation accelerator. The gelation kinetics, gel degradation, swelling and stiffness, were dependent on the identity of the functional groups, the identity of the cross-linkers, as well as on the concentration of the cross-linker and NVP. |

|||||||||||||||||||||||||||||||

For the complete references list and the full version of the review article published by JenKem Technology USA and Clarkson University please click visit the open source journal Modern Chemistry & Applications. |

|||||||||||||||||||||||||||||||

JenKem Technology provides PEG derivatives for 3D bioprinting of low toxicity PEG hydrogels for tissue engineering and organ scaffold manufacture.

A novel low toxicity photoinitiator for 3D Printing (M-QTX) was recently launched at the 2018 SFB meeting during the poster presentation session, please contact us for details.

To learn about additional applications of JenKem Technology PEGs, please visit our website.